2 月 . 18, 2025 05:54 Back to list

actuated gate valve

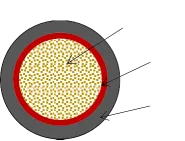

In the ever-evolving landscape of industrial operations, actuated gate valves stand as a paragon of precision and efficiency. These components are indispensable in various sectors, including oil and gas, pharmaceuticals, and water treatment, where controlling fluid flow is crucial. An actuated gate valve combines the mechanics of traditional gate valves with automation, ensuring optimal performance and minimal manual intervention. Understanding the intricacies of this device not only enhances operational efficiency but also fosters sustainable practices in resource management.

Trustworthiness is bolstered by transparent communication and robust after-sales support. Offering detailed documentation and user manuals that delineate installation, operation, and maintenance procedures fosters confidence among users. Additionally, providing access to customer support and technical expertise further assures clients that their operational needs will be met with diligence and promptness. Real-life application scenarios underscore the significance of actuated gate valves in streamlining operations. In a water treatment facility, for instance, these valves regulate the flow of water across various treatment stages, ensuring that the plant operates at peak efficiency while maintaining compliance with environmental standards. Similarly, in the oil and gas sector, actuated gate valves play a pivotal role in pipeline systems where precision flow control is paramount for safety and operational efficiency. As industries continue their digital transformation journeys, the integration of actuated gate valves with intelligent control systems is becoming increasingly prevalent. This convergence of mechanical engineering and digital technology allows for real-time monitoring and remote operation, facilitating proactive maintenance and reducing downtime. By capitalizing on the Internet of Things (IoT) and predictive analytics, organizations can optimize valve performance and lifespan, thus driving value and mitigating risks associated with mechanical failures. In conclusion, actuated gate valves epitomize the fusion of traditional engineering and modern innovation. Their adaptability and efficiency in fluid control systems render them indispensable in various industrial domains. By meticulously selecting and deploying these valves in accordance with industry standards and leveraging the latest technological advancements, organizations can enhance operational efficiency, ensure compliance, and achieve sustainable growth. With the right expertise and strategic foresight, actuated gate valves will continue to be a cornerstone in the pursuit of excellence in industrial fluid management.

Trustworthiness is bolstered by transparent communication and robust after-sales support. Offering detailed documentation and user manuals that delineate installation, operation, and maintenance procedures fosters confidence among users. Additionally, providing access to customer support and technical expertise further assures clients that their operational needs will be met with diligence and promptness. Real-life application scenarios underscore the significance of actuated gate valves in streamlining operations. In a water treatment facility, for instance, these valves regulate the flow of water across various treatment stages, ensuring that the plant operates at peak efficiency while maintaining compliance with environmental standards. Similarly, in the oil and gas sector, actuated gate valves play a pivotal role in pipeline systems where precision flow control is paramount for safety and operational efficiency. As industries continue their digital transformation journeys, the integration of actuated gate valves with intelligent control systems is becoming increasingly prevalent. This convergence of mechanical engineering and digital technology allows for real-time monitoring and remote operation, facilitating proactive maintenance and reducing downtime. By capitalizing on the Internet of Things (IoT) and predictive analytics, organizations can optimize valve performance and lifespan, thus driving value and mitigating risks associated with mechanical failures. In conclusion, actuated gate valves epitomize the fusion of traditional engineering and modern innovation. Their adaptability and efficiency in fluid control systems render them indispensable in various industrial domains. By meticulously selecting and deploying these valves in accordance with industry standards and leveraging the latest technological advancements, organizations can enhance operational efficiency, ensure compliance, and achieve sustainable growth. With the right expertise and strategic foresight, actuated gate valves will continue to be a cornerstone in the pursuit of excellence in industrial fluid management.

Share

Prev:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024