10 月 . 14, 2024 01:44 Back to list

actuated ball valve

Understanding Actuated Ball Valves An Overview

Actuated ball valves are integral components in various industrial processes, providing reliable control over fluid flow. They combine the functionality of traditional ball valves with the automation capabilities of actuators, making them essential in modern engineering applications. This article explores the design, benefits, and applications of actuated ball valves, highlighting their role in enhancing operational efficiency.

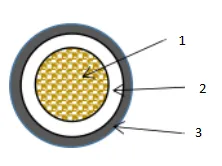

A ball valve is a type of valve that uses a spherical disc, known as a ball, to control the flow of liquids or gases. The ball has a hole or port through its center, allowing fluid to pass when aligned with the pipeline. When the ball is rotated 90 degrees, the flow is shut off. This design provides a robust sealing capability, enabling the valve to operate effectively in high-pressure and high-temperature environments.

The integration of an actuator transforms a manual ball valve into an actuated ball valve. Actuators can be powered by various energy sources, including electric, pneumatic, or hydraulic systems. They automatically open or close the valve based on predetermined conditions, such as pressure changes, temperature variations, or flow rates. This automation is essential for processes that require precise control and rapid response times.

actuated ball valve

One of the key advantages of actuated ball valves is their ability to improve efficiency and safety in industrial systems. By automating the flow control process, these valves reduce the risk of human error, ensuring that operations run smoothly. Additionally, they can be integrated into control systems that allow for remote monitoring and operation, making it easier for operators to manage complex processes from a distance.

Another benefit of actuated ball valves is their versatility. They are suitable for a wide range of applications across multiple industries, including oil and gas, chemicals, pharmaceuticals, water treatment, and food processing. This adaptability makes them a preferred choice for engineers looking to optimize operations in facilities that handle various fluids.

The durability of actuated ball valves is also noteworthy. They are constructed from high-quality materials such as stainless steel, carbon steel, or specialized alloys, allowing them to withstand corrosive environments and extend their lifespan. Regular maintenance and inspections can further enhance their reliability, ensuring continuous operation without unexpected downtime.

In conclusion, actuated ball valves play a crucial role in modern industry by providing effective flow control through automation. Their combination of reliability, efficiency, and versatility makes them indispensable in many applications. As industries continue to evolve and seek greater efficiency and safety in their operations, the use of actuated ball valves will undoubtedly increase, shaping the future of fluid management systems. By leveraging advancements in technology and engineering, these valves will continue to meet the demands of an ever-changing industrial landscape.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024