10 月 . 09, 2024 06:29 Back to list

8 inch check valve

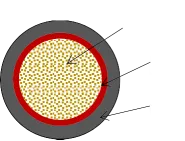

Understanding the 8-Inch Check Valve Functionality and Applications

An 8-inch check valve is a critical component in many fluid systems, widely used across various industries such as water treatment, oil and gas, and HVAC (Heating, Ventilation, and Air Conditioning). Check valves, often referred to as one-way valves, are designed to prevent the backward flow of fluid, ensuring that the direction of flow remains consistent and safe throughout the system.

What is a Check Valve?

A check valve is essentially a mechanical device that permits liquid or gas to flow through it in only one direction. When the flow direction reverses, the valve closes automatically, preventing backflow. The primary purpose of a check valve is to protect equipment, maintain system pressure, and improve operational efficiency.

Design and Operation

The design of an 8-inch check valve can vary depending on its application, but it typically consists of a body, a cover, a disc or ball, and a spring mechanism. In many cases, the valve employs gravity or spring tension to close the valve when the flow direction changes. The size of the valve, in this case, 8 inches, refers to the diameter of the opening, which is crucial for determining the flow capacity and compatibility with existing piping systems.

The operation of the check valve is straightforward. When fluid enters the valve from the designated inlet side, the pressure forces the disc or ball to open, allowing fluid to pass through. Once the flow ceases or reverses, the pressure is relieved, and the valve automatically closes, creating a tight seal that prevents backflow.

Applications of 8-Inch Check Valves

8 inch check valve

The versatility of 8-inch check valves makes them suitable for various applications

1. Water and Wastewater Management In municipal water systems, check valves help maintain the flow of water and prevent contamination from backflow. In wastewater treatment facilities, they protect pumps and other equipment from the adverse effects of backflow.

2. Oil and Gas Industry Check valves are essential in oil and gas pipelines where they prevent backflow that could lead to safety hazards, spills, or damage to equipment. They help maintain pressure and ensure the safe transport of fluids.

3. HVAC Systems In heating and cooling systems, check valves help maintain the desired flow of air or water, preventing reverse flow that can lead to inefficiencies or system damage.

4. Industrial Processes Many manufacturing processes require precise control of fluid flow. Check valves are integral to maintaining the efficiency and safety of such operations by preventing backflow and ensuring a steady supply of materials.

Conclusion

In conclusion, the 8-inch check valve plays a vital role in ensuring the efficient and safe operation of fluid systems across multiple industries. Its ability to prevent backflow enhances the functionality of pumps, protects equipment, and maintains the integrity of various processes.

When selecting a check valve, it is essential to consider factors such as the type of fluid being transported, operating pressure, temperature, and the specific requirements of the application. Regular maintenance and inspection of check valves are also crucial to ensure their reliability and longevity. Overall, investing in a quality 8-inch check valve can lead to improved system performance and enhanced safety in fluid handling operations.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024