2 月 . 13, 2025 00:18 Back to list

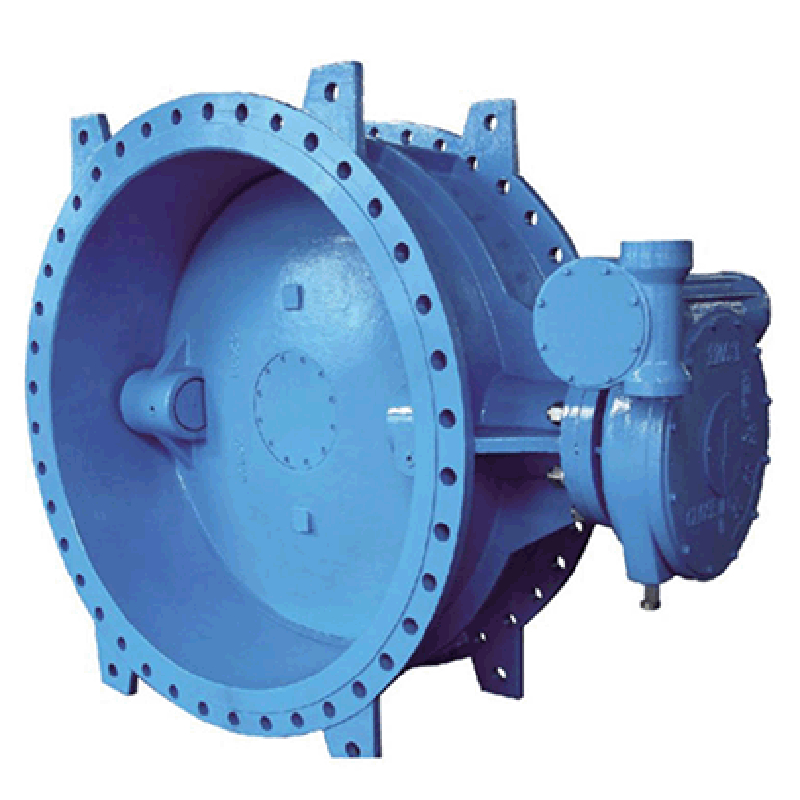

6 inch ball valve

Choosing the right ball valve for industrial applications requires a comprehensive understanding of the product's functionalities and its impact on systems where it's implemented. Among various options, the 6-inch ball valve holds a significant place in industrial processes, offering distinct advantages that cater to specific operational needs.

Maintenance and operational efficiency are key drivers for selecting a 6-inch ball valve. The design facilitates easy inspection and repair since most models incorporate a two-piece or three-piece body, which allows for in-line maintenance without disrupting the entire pipeline system. Such features enhance system uptime and reduce maintenance costs, making them a cost-effective solution over the valve's lifecycle. When integrating automation in fluid systems, many industries opt for actuated 6-inch ball valves. These can be electric, pneumatic, or hydraulic, providing precise control and quick response times, which are essential for remote operations and process optimization. This adaptability makes them suitable for modern smart systems that require seamless integration with SCADA or other process control systems. The authority of manufacturers specializing in 6-inch ball valves is a testament to the product's quality and reliability. Leading manufacturers adhere to stringent industry standards, such as ISO, API, and ANSI, ensuring that each valve is engineered to meet or exceed performance expectations. This compliance instills trust among users who rely on these components for critical applications. Experience with these valves reveals a solid track record of performance over various installations worldwide. Expert engineers and field technicians consistently report positive outcomes, noting the valve's ability to handle extreme conditions and maintain high flow rates without compromising on sealing performance. In conclusion, the 6-inch ball valve stands as an indispensable component in industrial systems, delivering efficiency, reliability, and safety. Its design advancements cater to demanding application requirements, and its adaptability means it keeps pace with technological progressions in automated environments. Companies investing in 6-inch ball valves can expect long-term benefits, grounded in the authority and expertise of seasoned manufacturers committed to producing industry-leading solutions.

Maintenance and operational efficiency are key drivers for selecting a 6-inch ball valve. The design facilitates easy inspection and repair since most models incorporate a two-piece or three-piece body, which allows for in-line maintenance without disrupting the entire pipeline system. Such features enhance system uptime and reduce maintenance costs, making them a cost-effective solution over the valve's lifecycle. When integrating automation in fluid systems, many industries opt for actuated 6-inch ball valves. These can be electric, pneumatic, or hydraulic, providing precise control and quick response times, which are essential for remote operations and process optimization. This adaptability makes them suitable for modern smart systems that require seamless integration with SCADA or other process control systems. The authority of manufacturers specializing in 6-inch ball valves is a testament to the product's quality and reliability. Leading manufacturers adhere to stringent industry standards, such as ISO, API, and ANSI, ensuring that each valve is engineered to meet or exceed performance expectations. This compliance instills trust among users who rely on these components for critical applications. Experience with these valves reveals a solid track record of performance over various installations worldwide. Expert engineers and field technicians consistently report positive outcomes, noting the valve's ability to handle extreme conditions and maintain high flow rates without compromising on sealing performance. In conclusion, the 6-inch ball valve stands as an indispensable component in industrial systems, delivering efficiency, reliability, and safety. Its design advancements cater to demanding application requirements, and its adaptability means it keeps pace with technological progressions in automated environments. Companies investing in 6-inch ball valves can expect long-term benefits, grounded in the authority and expertise of seasoned manufacturers committed to producing industry-leading solutions.

Share

Prev:

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024