12 月 . 03, 2024 19:04 Back to list

3 way globe valve

Understanding 3-Way Globe Valves Design, Functionality, and Applications

3-way globe valves play a crucial role in fluid control across various industries, including chemical processing, water treatment, and HVAC systems. Their unique design allows them to serve multiple functions, such as mixing or diverting flow, making them an essential component in many piping systems.

Design Features

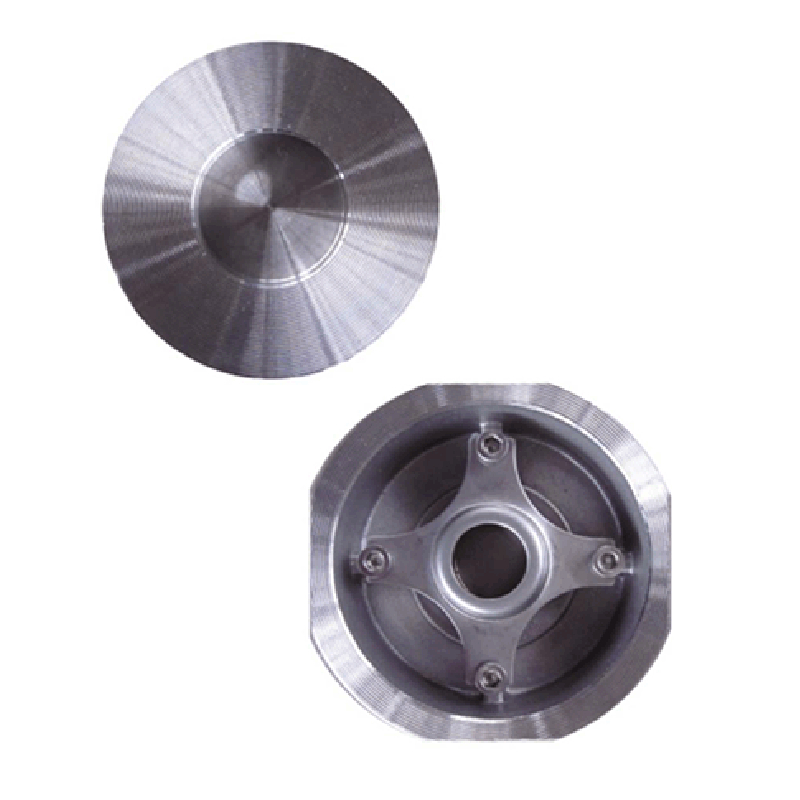

A 3-way globe valve is characterized by its three ports one inlet and two outlets. The flow can be directed between the two outlets, which provides versatility in its operation. The valve body is often constructed from materials such as stainless steel, bronze, or plastic, selected based on the specific application and the type of fluid being handled. The distinctive globe shape of the valve minimizes turbulence and pressure drop, enabling smoother flow through the valve compared to other designs.

The internal mechanism typically consists of a disc, which is attached to a stem. When the stem is turned, the disc moves up or down, allowing or restricting the flow of fluid through the valve. This movement can be manual or automated, depending on the valve configuration—manual valves are operated using a handwheel, while automated valves may be actuated by electric, pneumatic, or hydraulic systems.

Functionality

One of the primary functions of a 3-way globe valve is to facilitate mixing or splitting fluid flows. For example, in a heating system, a 3-way globe valve can mix two different water streams at varying temperatures to achieve a desired output temperature. This ability to blend or divert flows allows for improved efficiency and control in various processes.

The configuration of the ports determines the valve's mode of operation

3 way globe valve

1. Mixing Valve Configuration In this arrangement, one inlet flows into two outlets. This type of operation is typically used when blending fluids of different temperatures or compositions is essential, allowing for precise temperature regulation in heating systems.

2. Diverting Valve Configuration Conversely, in a diverting setup, the valve allows one inlet to direct flow to one of the two outlets based on system requirements. This functionality is useful in systems where flow direction needs to be altered frequently or where bypassing one line is necessary without stopping the operation of the system.

Applications

The versatility of 3-way globe valves makes them suitable for a wide array of applications. In the chemical industry, they are widely employed for regulating the mix of different chemicals in reactors and ensuring precise dosing in mixing operations. In HVAC systems, these valves play a vital role in maintaining temperature control by mixing cooled and heated air or liquids.

Moreover, in water treatment plants, 3-way globe valves help manage the distribution of treated water to various points in the pipeline. This capability is crucial for maintaining water quality and flow consistency across the network.

Advantages

Using 3-way globe valves provides numerous advantages. Their robust design ensures long-lasting performance, while their ability to handle high pressures and temperatures makes them suitable for demanding environments. Additionally, their compact design can save space in installations compared to larger, more complex valve configurations.

In summary, 3-way globe valves are an integral part of modern fluid control systems. With their ability to effectively mix or divert flows, along with durable design and versatility, they are employed across many sectors to enhance process efficiency and fluid management. Understanding their functionality and applications can aid in choosing the right valve for specific needs, ultimately leading to improved system performance and operational reliability.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024