10 月 . 12, 2024 15:16 Back to list

3 way air valve

Understanding the 3-Way Air Valve Functionality, Applications, and Benefits

In industrial applications where air and gas flow control is essential, the design and utility of valves become paramount. Among these, the 3-way air valve emerges as a critical component. This article delves into the functionality, applications, and advantages of the 3-way air valve system, providing insights into its significance in various industries.

What is a 3-Way Air Valve?

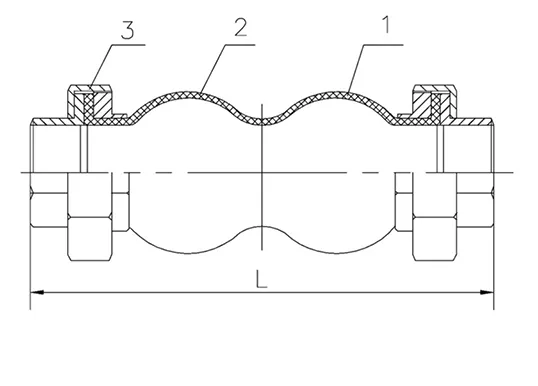

A 3-way air valve is a type of valve that has three ports one inlet and two outlets. The valve can control the flow of air between these ports, allowing for the distribution or diversion of air from one source to multiple destinations. Typically, these valves can be configured in various ways to either allow the flow to be sent to one of the two outlet ports or to simultaneously connect the two outlet ports.

In a common configuration, the 3-way valve operates in two distinct modes normally open and normally closed. The mode determines how air is allowed to flow when the valve is in its default state. The switching mechanism can be pneumatic, electric, or mechanical, providing flexibility depending on the application.

Functionality of the 3-Way Air Valve

The primary role of the 3-way air valve is to manage the distribution of compressed air in a system. By directing the air flow, the valve plays a crucial role in the operation of pneumatic systems, enabling machines and actuators to function efficiently.

1. Directing Air Flow The valve can be switched between its two positions, controlling which outlet receives airflow. This is particularly useful in applications like pneumatic cylinders, where the direction of movement must be controlled.

2. Mixing and Diverting In more advanced setups, a 3-way air valve can mix different air streams or divert air based on the operational needs. This versatility enhances system performance and efficiency.

3. Pressure Control By integrating pressure sensors and electronic controls, the 3-way air valve can maintain optimal pressure levels in a pneumatic system, ensuring component longevity and effective operation.

Applications of 3-Way Air Valves

The application of 3-way air valves spans various industries, each benefiting from their versatile functionality

.1. Manufacturing In manufacturing plants, 3-way valves are essential for controlling pneumatic systems that operate tools, machinery, and assembly lines. They help regulate airflow, allowing for seamless transitions between different production tasks.

3 way air valve

2. Automotive Industry In automotive assembly and repair, these valves control pneumatic tools that require precise airflow to function correctly. They also direct air flows for painting and other processes where consistent pressure is crucial.

3. Food and Beverage The food and beverage sector employs 3-way air valves in packaging processes, where they contribute to maintaining hygiene while controlling the flow of air in vacuum packing and bottling.

4. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, 3-way valves are used to control airflow and temperature regulation, ensuring comfort in residential and commercial buildings.

5. Robotics In automation and robotics, the 3-way air valve plays a critical role in controlling actuators and moving parts. Its precision and reliability are vital for synchronizing complex movements.

Advantages of Using 3-Way Air Valves

Implementing 3-way air valves in systems comes with numerous benefits

1. Versatility The ability to connect, divert, or mix airflows provides significant flexibility in system design and operation.

2. Space Saving By integrating multiple functions into a single unit, 3-way valves reduce the need for multiple components, saving space and simplifying installations.

3. Improved Efficiency With better control of air distribution, systems can operate more efficiently, leading to energy savings and reduced operational costs.

4. Enhanced Control Precise control over airflow leads to improved performance of equipment and systems, minimizing the risk of errors or malfunctions.

5. Durability Most 3-way air valves are built to withstand the rigors of industrial applications, leading to longer service life and lower maintenance costs.

Conclusion

The 3-way air valve is an indispensable component in modern industrial operations, offering versatility, efficiency, and enhanced control in managing airflow. As industries continue to evolve and improve their processes, the significance of such valves will undoubtedly increase, highlighting their role in the advancement of technology and manufacturing. Understanding the functionalities and advantages of 3-way air valves not only aids in selecting the right components for specific applications but also promotes the development of more efficient and reliable pneumatic systems.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024