9 月 . 07, 2024 22:10 Back to list

High-Quality 3 Piece Ball Valve for Reliable Fluid Control

Understanding 3-Piece Ball Valves A Comprehensive Overview

In the realm of industrial applications, valves play a critical role in regulating the flow of fluids. Among various types of valves, the 3-piece ball valve stands out for its design and functionality. This article explores the unique features, benefits, and applications of 3-piece ball valves, making it clear why they are a preferred choice in many industries.

What is a 3-Piece Ball Valve?

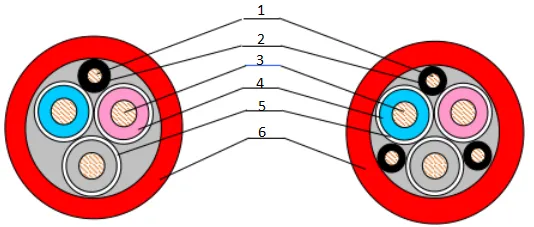

A 3-piece ball valve consists of three primary components the body, the ball, and the actuator. The design usually incorporates two end connections and a center section, which is easily removable. This configuration allows for maintenance and repair without needing to remove the entire valve from the pipeline, thereby minimizing downtime.

Typically made from high-quality materials such as stainless steel, carbon steel, or brass, these valves can withstand varying levels of pressure and temperature. The ball within the valve has a bore that allows for fluid flow when in an open position and prevents flow when turned 90 degrees to the pipe.

Key Features of 3-Piece Ball Valves

One of the most notable features of 3-piece ball valves is their versatility. They are available in a variety of sizes and pressure ratings, catering to different industrial needs. The design also allows for easy installation and disassembly, making maintenance straightforward.

3 piece ball valve

Furthermore, 3-piece ball valves exhibit excellent sealing capabilities. The seats are typically made of resilient materials that provide a tight seal, minimizing leaks and ensuring system integrity. This is crucial in industries where even minor leaks can lead to significant safety hazards or operational losses.

The ability to operate smoothly under both low and high flow conditions makes them suitable for various applications, from water treatment to gas distribution, and food processing to pharmaceutical manufacturing.

Applications

The applications of 3-piece ball valves are vast and varied. They are commonly used in

1. Oil and Gas Industry For controlling the flow of oil and gas in pipelines and refineries, ensuring safe and efficient operation. 2. Water Treatment In plants where precise flow control is essential, these valves help manage the treatment processes. 3. Food and Beverage They meet sanitary standards, making them ideal for controlling flow in food production and processing. 4. Pharmaceutical Manufacturing Their ease of cleaning and maintenance ensures compliance with stringent health regulations.

Conclusion

In summary, the 3-piece ball valve is a remarkable component in modern engineering and industrial applications. Its durable construction, ease of maintenance, and reliable performance make it indispensable across various sectors. As industries continue to evolve, the 3-piece ball valve will undoubtedly maintain its status as a crucial element in flow control and management systems. Whether you're an engineer, a maintenance technician, or involved in system design, understanding the benefits and applications of 3-piece ball valves can lead to more efficient and reliable processes.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024