9 月 . 21, 2024 17:32 Back to list

2 inch ball check valve

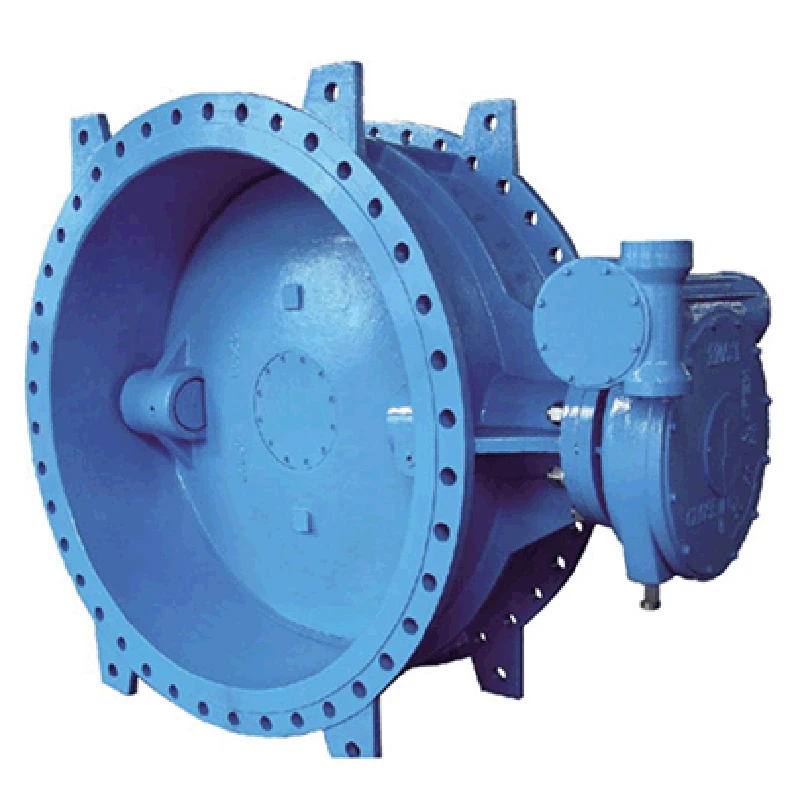

Understanding the 2 Inch Ball Check Valve

In various industrial applications where fluid control is crucial, the ball check valve has emerged as a reliable solution. A specific type that often garners attention is the 2 inch ball check valve. This valve is designed to prevent backflow in pipelines, ensuring that fluids flow in one direction only. With its compact design and efficient operation, it serves various sectors, including water treatment, oil and gas, and chemical processing.

Design and Operation

The 2 inch ball check valve operates on a simple yet effective principle the ball, which is located in the valve body, moves upward to allow fluid to pass when the pressure from the inlet is greater than the pressure at the outlet. Conversely, when the pressure from the outlet is higher, the ball is forced back into its seat, effectively sealing the valve and preventing backflow. This mechanism is essential for maintaining the integrity of fluid systems and preventing contamination of the incoming flow.

Advantages of the 2 Inch Ball Check Valve

One of the most significant advantages of the 2 inch ball check valve is its simplicity. The design has few moving parts, which translates to lower maintenance and repair requirements compared to other types of check valves. Furthermore, the valve can handle a wide range of pressures and temperatures, making it versatile for different applications. Its compact size makes it easy to install in tight spaces, a common requirement in many industrial settings.

2 inch ball check valve

Another benefit is its effectiveness in preventing backflow, which is critical in applications where fluid contamination poses significant risks. By ensuring that fluid can only flow in one direction, the 2 inch ball check valve protects equipment and maintains system efficiency.

Installation and Maintenance

Installing a 2 inch ball check valve is relatively straightforward, but it requires attention to detail to ensure optimal performance. It’s essential to position the valve so that the fluid flows in the correct direction, as indicated by the arrow marked on the valve body. Regular maintenance checks can help identify any potential issues, such as wear on the ball or seat, which could lead to leaks or malfunctions.

Cleaning the valve periodically can help in maintaining its function. In corrosive or high-sediment applications, additional care may be necessary to ensure longevity and reliability.

Conclusion

In summary, the 2 inch ball check valve is an essential component in many fluid control systems. Its reliability, ease of installation, and low maintenance needs make it a preferred choice in various industries. By preventing backflow effectively, this valve plays a critical role in maintaining system integrity and ensuring the safe transfer of fluids. As industries continue to evolve, the importance of such simple yet effective devices will undoubtedly remain a cornerstone in fluid management solutions.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024