10 月 . 21, 2024 02:54 Back to list

1400mm Butterfly Valve Specifications and Applications for Optimal Performance

Understanding the 1400mm Butterfly Valve Features, Applications, and Benefits

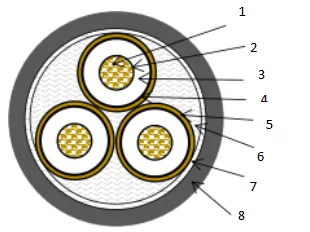

A butterfly valve is a type of flow control device that is used to regulate the flow of fluids through a pipe. The 1400mm butterfly valve specifically refers to a valve with a diameter of 1400 millimeters, making it a substantial choice for various industrial applications. This article delves into the features, applications, and benefits of using a 1400mm butterfly valve in different industries.

Features of the 1400mm Butterfly Valve

1. Construction Material Butterfly valves can be constructed from various materials, including stainless steel, cast iron, and plastic. The choice of material affects durability and resistance to corrosion, making it vital for industries requiring high levels of hygiene and strength.

2. Design The valve consists of a disk or a plate that rotates around a central axis. When the valve is fully closed, the disk blocks the flow; when fully opened, the disk is parallel to the flow direction, allowing for minimal resistance. This simple yet effective design enables quick operation.

3. Actuation The 1400mm butterfly valve can be operated manually or through automated systems. Electric actuators, pneumatic actuators, or hydraulic systems can provide the necessary force to open or close the valve, enhancing efficiency and reducing labor costs.

4. Sealing Mechanism A reliable sealing mechanism is crucial for preventing leaks. Most butterfly valves utilize either elastomeric seals or metal-to-metal seals, ensuring effective isolation of the flow when in the closed position.

Applications of the 1400mm Butterfly Valve

1. Water Treatment Plants Butterfly valves are widely used in water treatment facilities for regulating the flow of water in various stages of the treatment process. Their ability to provide tight sealing and quick operation is essential for maintaining optimal performance.

2. Chemical and Petrochemical Industries In these industries, the 1400mm butterfly valve is utilized for controlling the flow of fluids that may be corrosive or hazardous. Their robust construction and reliability make them suitable for handling challenging materials.

1400mm butterfly valve

3. HVAC Systems Heating, ventilation, and air conditioning systems often incorporate butterfly valves to manage airflow and temperature. The large size of the 1400mm valve makes it suitable for large-scale HVAC applications in commercial buildings.

4. Mining and Mineral Processing In mining applications, butterfly valves are used to control slurry flows, which can be abrasive. Their ability to handle tough conditions while remaining functional is a significant advantage in these environments.

Benefits of Using a 1400mm Butterfly Valve

1. Space Efficiency Due to their compact design, butterfly valves occupy less space compared to gate or globe valves, making them ideal for installations where space is limited.

2. Cost-Effectiveness With lower material costs and the ability to automate operations, butterfly valves can be a more economical choice for large-scale projects.

3. Reduced Flow Resistance When fully opened, the disk of a butterfly valve creates minimal flow resistance, which helps in maintaining energy efficiency in various applications.

4. Ease of Maintenance The simple design of the butterfly valve allows for easy maintenance and replacement of parts, reducing downtime in industrial operations.

Conclusion

The 1400mm butterfly valve is an essential component in numerous industries due to its versatility, efficiency, and reliability. Understanding its features, applications, and benefits can help engineers and decision-makers choose the right valve for their specific needs, leading to improved performance and productivity in their operations. As industries continue to evolve, the demand for effective flow control solutions like the 1400mm butterfly valve will only grow.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024