9 月 . 02, 2024 01:47 Back to list

High-Quality 12-Inch Knife Gate Valve for Reliable Isolation and Control

Understanding the 12% Knife Gate Valve A Crucial Component in Fluid Control

The 12% knife gate valve is an essential component in various industrial applications, particularly in the management and control of fluid flow in pipelines. Unlike traditional gate valves, knife gate valves are designed with a sharp blade that can effectively cut through slurries, thick liquids, and other challenging materials, ensuring reliable operation in demanding conditions.

What Is a Knife Gate Valve?

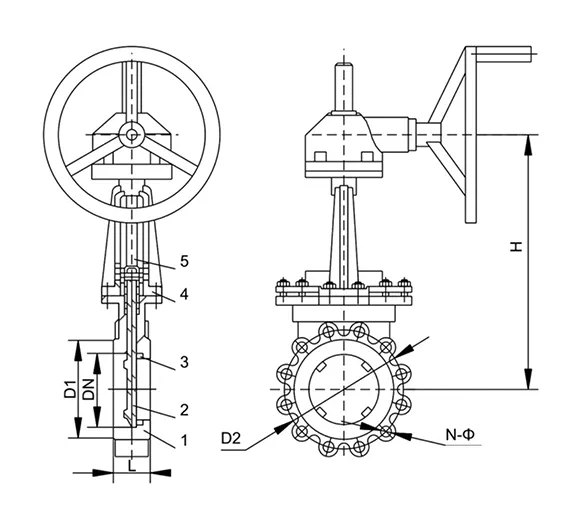

A knife gate valve consists of a blade-shaped disk that is raised or lowered within the valve body to either allow or block fluid flow. Its unique design makes it suitable for handling materials that are not easily managed by standard valves. The knife action allows the valve to slice through thick media, such as slurries containing solid particles, without becoming plugged or damaged.

Importance of the 12% Design

The designation 12% refers to the specific design parameter of the valve related to its performance characteristics, often in terms of its flow coefficient (Cv) or the percentage of opening needed for optimal operation. A 12% knife gate valve is optimized to provide efficient flow control with minimal pressure drop when fully opened, making it an ideal choice for processes that require precise adjustments in fluid dynamics.

12 knife gate valve

Applications in Various Industries

Knife gate valves, particularly those with a 12% design, are widely used in industries such as wastewater treatment, mining, pulp and paper production, and chemical processing. In wastewater treatment, they play a vital role in controlling the flow of sewage and sludge, ensuring that treatment processes run smoothly. In mining and mineral processing, these valves manage the flow of slurries, reducing the risk of blockages and improving efficiency.

Key Benefits

One of the most significant advantages of the 12% knife gate valve is its ease of maintenance. The simple design minimizes the number of moving parts, which reduces wear and tear and makes repairs straightforward. Additionally, these valves are typically constructed from durable materials, enabling them to withstand corrosive environments and extend their lifespan.

Conclusion

In summary, the 12% knife gate valve is a critical element in managing fluid flow in various industrial applications. Its innovative design allows for effective handling of challenging materials, making it a preferred choice for industries that require reliable and efficient fluid control mechanisms. As industries continue to evolve, the demand for versatile and durable solutions like the knife gate valve will undoubtedly grow, underscoring the importance of these components in modern engineering and infrastructure.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024